We always told the printer to extrude the same amount of filament but the weight of the extruded material slowly decreases at higher speeds. This is already an indication that at this point the setup is overwhelmed, but the even more interesting thing is putting these extrusions on a scale and weighing them.

Increasing it higher made it skip even more often. This was at 15mm³/s extrusion rate and would be equivalent to 0.3mm layers with a 0.4mm nozzle at 100mm/s.

At some point, with my particular setup which is a Prusa i3 MK3s with the E3D V6 hotend, the filament starts skipping from time to time. The lowest speed is equivalent to printing with a 0.4mm nozzle at 0.12mm layers at 50mm/s. Really worth watching! So I started extruding the material at a slow 3mm³/s and increased it in 3mm³/s steps.

Reminds me of probably the first video I’ve ever seen by SmarterEveryDay many years back and where Destin shows the same property and mathematical description using honey. The material settles on the build platform and creates these really nice, round structures which diameter is varying depending on the extrusion temperature and therefore softness or viscosity of the material. I prepared a short GCODE in which I first prime the nozzle with 20mm of filament, then pause a tiny amount of time in which I manually remove the string and continue extruding half a meter of filament at a set speed. After of course loading the filament into your printer, in my case, I used Purple PLA from RedLineFilament, you set it to the temperature you usually print at. Link to a suitable scale in the description by the way. The only thing that you need is a fairly precise scale and a roll of filament that doesn’t vary that much in diameter. In order test out the capabilities of my setup, I came up with a very simple test that you can also perform on your own. I’ve even seen these fancy nozzles that claim higher melting capability since the surface area is increased by its shape.

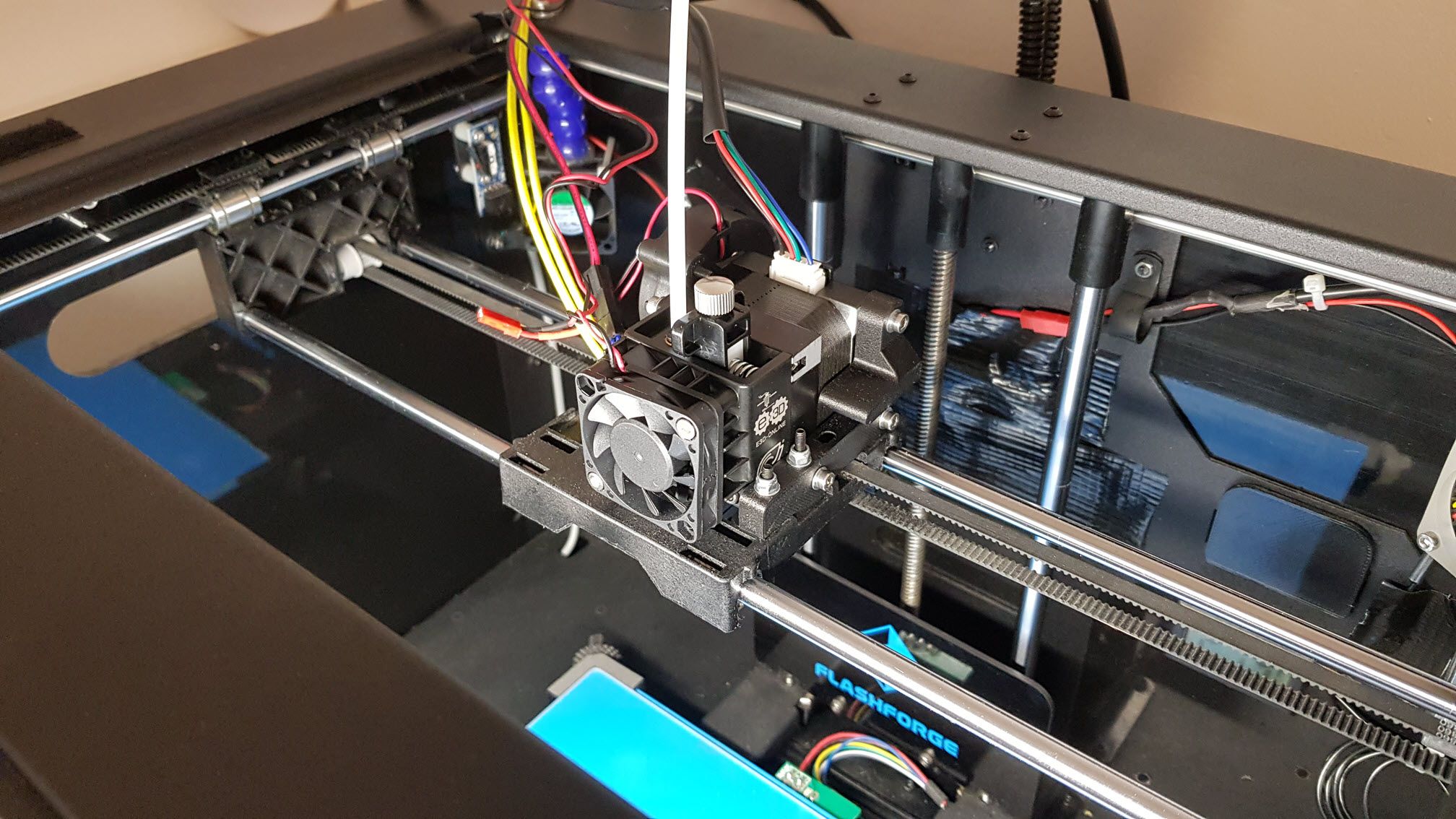

#Hemera e steps upgrade#

The question now is, how you can find out what is still possible with your current setup and when it might be a good idea to upgrade to a volcano heater block. Bigger nozzles and the often-resulting thicker layers though can drastically increase that value. If you’re printing with a standard 0.4mm nozzle, this value is usually single digit, if you’re not going crazy fast. This property is linearly proportional to the printing speed, nozzle diameter and layer height and can be visualized for example in PrusaSlicer. The material throughput is usually characterized by the flow rate so the amount of material that is pushed though the extruder per second. They use longer nozzles and give the filament more time to properly heat and melt before the plastic leaves the nozzle. I think everyone has already heard that for printing faster and especially with bigger nozzles a so called volcano hotend might be necessary. The hotends of common 3D printers look pretty much the same and mostly use these small nozzles where the material is melted.

0 kommentar(er)

0 kommentar(er)